current location:Home > Product & Capacity > Product Category

more

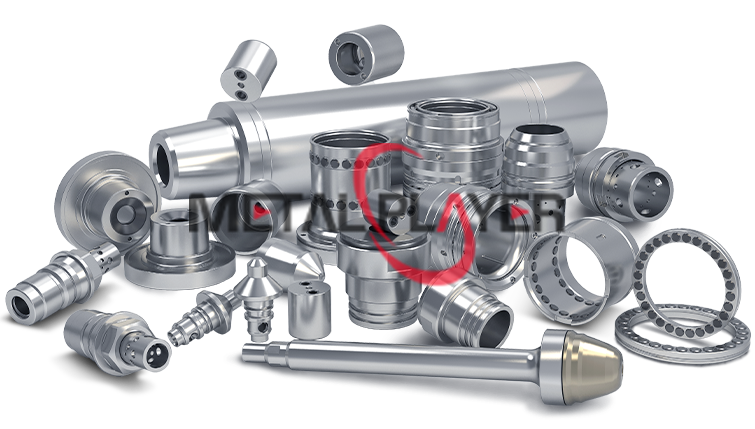

Cemented Carbide is achieved by powder metallurgy process with ultra-fine powders of one or several refractory carbides (tungsten carbide, titanium carbide, etc.) as the main component and through the addition of a metallic powder as binder (such as cobalt or nickel, etc.). It is mainly used for manufacturing high-speed cutting tools and cutting tools for hard & tough materials, as well as for making cold working dies, Gauge, and high wear-resistant parts that are not affected by impact and vibration. Advantages: Can produce all non- standard size parts, especially large size products, Maximum size: 450mm*450mm

more

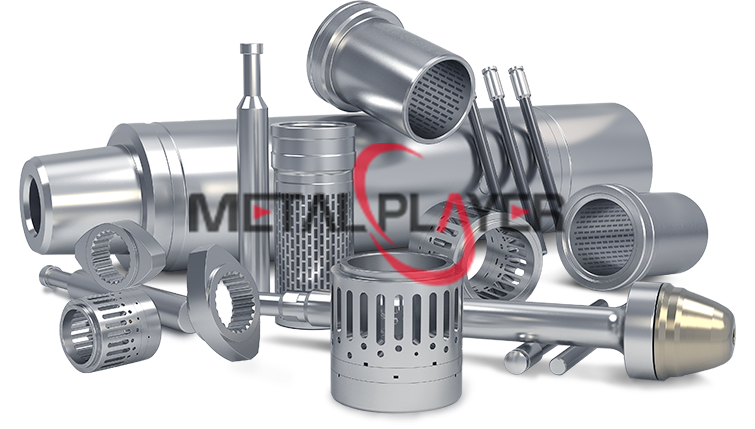

Material for surface enhancement is composed of a variety of nano-scale mineral materials and a variety of auxiliary materials, using lubricating oil or grease as a carrier and enters the mechanical friction surface. The friction heat energy generated during mechanical movement causes the "dry constant material" adsorbed and permeated on the metal friction surface to release active substances, and these active substances undergo mechanochemical reactions with the metal surface - fusion, oxidation renewal, self-adaptive modification. Main Technologies: PTA, HVOF, Gas shielded welding, Flame cladding, Vacuum cladding.

more

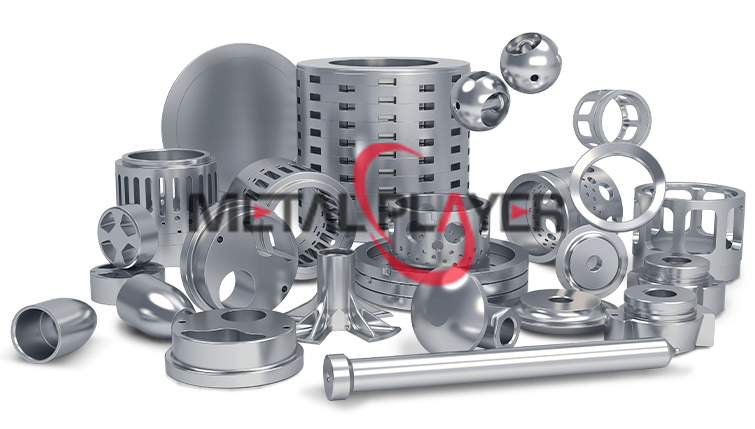

Metal composite material refers to the composite material formed by metallurgical combination of various metals with different chemical and mechanical properties on the interface by using composite technology, which greatly improves the thermal expansion, strength, fracture toughness, impact toughness, abrasion resistance, electrical performance, magnetic performance and other properties of a single metal material, and is widely used in petroleum, chemical industry, shipbuilding, metallurgy, mining, machinery manufacturing, power, water conservancy, transportation Environmental protection, pressure vessel manufacturing, food, brewing, pharmaceutical and other industrial fields.